Welding Tabs from China - Reliable Manufacturer for Quality Solutions

As a dedicated professional in the welding industry, I know how crucial it is to have reliable welding tabs for your projects. Our welding tabs, manufactured in China, are designed with precision to meet diverse application needs. Whether you’re in automotive, construction, or any other sector, these tabs ensure secure attachments and strong joints, making your workflow smoother and more efficient. I understand the importance of partnering with a trustworthy manufacturer. That's why our team prioritizes quality and durability, so you can trust that our welding tabs will perform under pressure. Plus, sourcing from China allows us to offer competitive prices without compromising on quality. When you choose our welding tabs, you're not just making a purchase; you're investing in your project’s success. Let’s elevate your work together with top-notch products that deliver results every time. Reach out to explore how our welding tabs can make a difference for you!

Welding tabs Manufacturer Trusted by Pros

In the competitive landscape of manufacturing, selecting the right welding tabs supplier can make all the difference for professionals aiming for quality and reliability. With a reputation built on years of experience, a top-tier welding tabs manufacturer understands the diverse needs of clients across various industries. They ensure that each product adheres to stringent quality standards, offering a range of options tailored for specific applications, whether in automotive, construction, or fabrication sectors. What sets a trusted manufacturer apart is not only the quality of their welding tabs but also their commitment to customer satisfaction. By providing excellent support, timely delivery, and scalability, these manufacturers become invaluable partners in the supply chain. In addition, advanced manufacturing techniques and materials ensure that their products can withstand the rigors of heavy-duty applications, thus enhancing efficiency and performance for users. Moreover, this trusted manufacturer keeps pace with technological advancements and industry trends, ensuring that clients receive innovative solutions designed to meet the evolving demands of their businesses. By integrating feedback from professionals, they continuously refine their offerings, making them the go-to choice for anyone looking to ensure superior quality and reliability in their welding processes. As global procurement becomes increasingly interconnected, partnering with a reputable welding tabs manufacturer is essential for professionals eager to stay ahead in their respective fields.

Welding Tabs Manufacturer Trusted by Pros

| Material Type | Thickness (mm) | Dimensions (mm) | Tensile Strength (MPa) | Application |

|---|---|---|---|---|

| Mild Steel | 3.0 | 50 x 20 | 250 | General Fabrication |

| Stainless Steel | 2.5 | 40 x 15 | 520 | Food Processing |

| Aluminum | 1.5 | 30 x 10 | 310 | Aerospace |

| High Carbon Steel | 4.0 | 60 x 25 | 600 | Construction |

| Copper | 2.0 | 35 x 12 | 210 | Electrical Components |

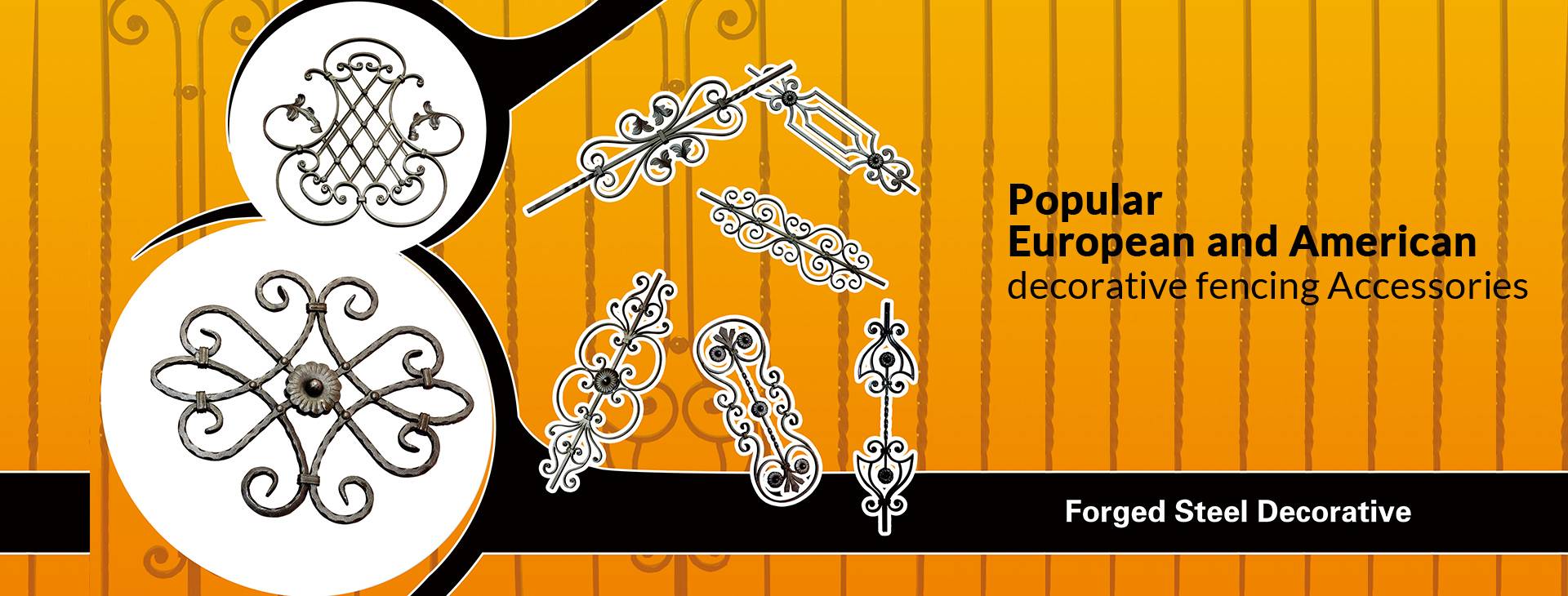

Related Products