Top Forging Manufacturers in China: Quality & Precision Guaranteed

As a supplier immersed in the world of forging, I understand the critical role that quality and reliability play in your manufacturing processes. Based in China, I take pride in being a manufacturer that delivers top-notch forged products tailored to meet your specifications. Our extensive range of offerings includes everything from precision components to heavy-duty parts, all crafted with state-of-the-art techniques and materials. I believe in building partnerships based on trust and transparency, ensuring that your needs are met every step of the way. With over [X years] of experience, I’ve seen firsthand how our attentive service and commitment to quality can elevate your project’s success. When you choose us, you're not just getting products; you're gaining a dedicated ally in your manufacturing endeavors. Let’s connect to discuss how our forging solutions can support your business goals and help you stay ahead in the competitive market.

Forging Is The Best Ahead of the Curve

In today's competitive global market, understanding the advantages of advanced manufacturing processes is crucial for procurement professionals seeking high-quality products. Among these methods, forging stands out as a method that not only enhances the mechanical properties of materials but also ensures precision and durability. This technique allows manufacturers to produce components that meet the rigorous demands of various industries, from automotive to aerospace, making it an indispensable choice for businesses striving for excellence. One of the primary benefits of forging is its ability to create stronger and more resilient parts compared to other manufacturing methods. The process aligns the internal grain structure of the metal, resulting in improved strength and toughness. Moreover, forgings exhibit superior fatigue resistance, making them ideal for high-performance applications. By choosing forged products, global buyers can ensure they are investing in items that will withstand the test of time, ultimately reducing costs and enhancing product reliability. Embracing forging technology allows procurement professionals to stay ahead of the curve in their respective industries. As demand for lightweight yet strong components continues to rise, the ability to leverage cutting-edge forging techniques will be paramount. By focusing on this manufacturing process, businesses can enhance their supply chains, meet evolving consumer needs, and maintain a competitive edge in a rapidly changing marketplace. In this pursuit, aligning with forward-thinking manufacturers who prioritize innovation is essential for long-term success.

Forging Is The Best Ahead of the Curve

| Technique | Material Type | Advantages | Applications | Market Trends |

|---|---|---|---|---|

| Open Die Forging | Steel | Versatile; High strength | Aerospace; Automotive | Growing demand in aerospace |

| Closed Die Forging | Aluminum | Complex shapes; Reduced waste | Consumer electronics; Aerospace | Increased efficiency in production |

| Ring Forging | Alloy Steel | High integrity; High performance | Oil & Gas; Renewable energy | Focus on high-performance applications |

| Isothermal Forging | Titanium | Improved toughness; Enhanced properties | Aerospace components | Rising interest in lightweight materials |

| Superplastic Forming | Zinc Alloy | Highly ductile; Shape adaptability | Automotive; Aerospace | Innovation for high complexity parts |

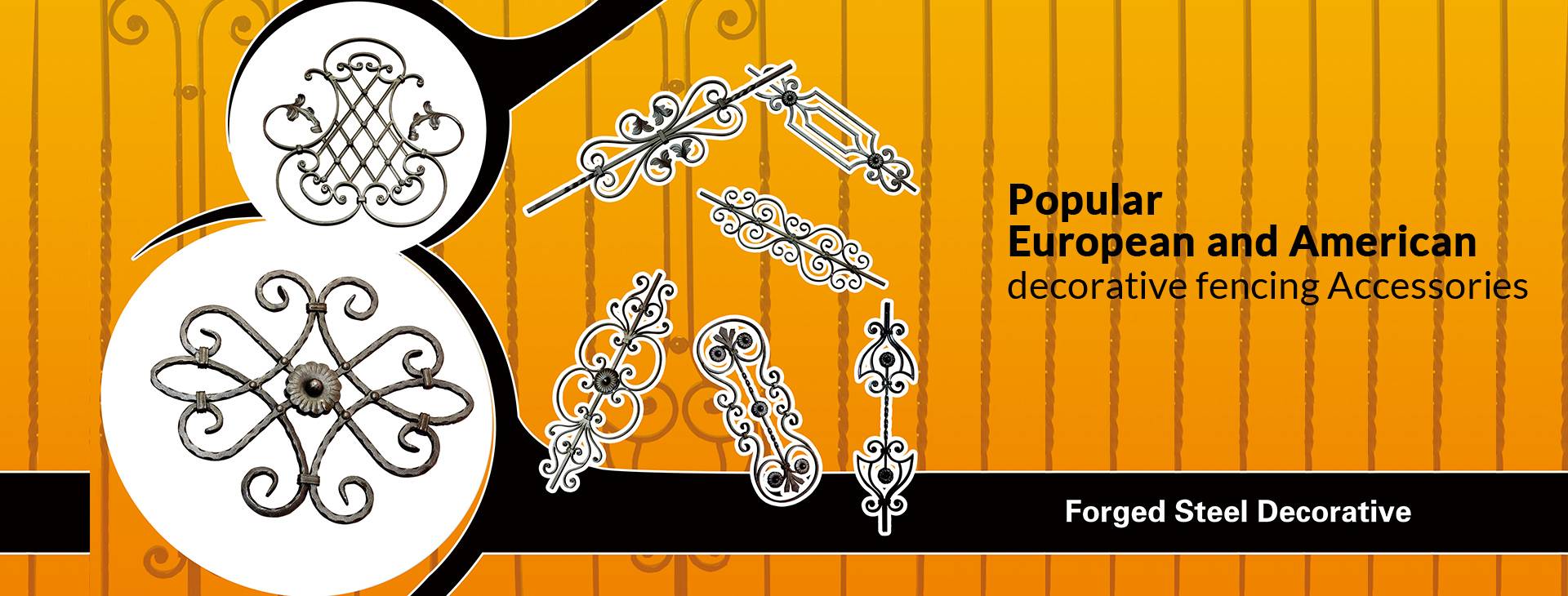

Related Products